Liner

Company Email: hbhezhong@163.com

Sale Email: siyongfei@hbhzgs.com

Tel: +86 4001033112

Whatsapp: +86 17352998802

Wear-resistant cast steel liner:

Material characteristics:

Wear-resistant cast steel adopts melting casting forming method, which adds chromium, manganese and other elements, greatly improve its wear resistance, impact resistance, with high hardness, its economic type has a wide range of applications for high wear-resistant scenes.

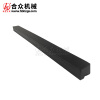

Surfacing liner:

Material characteristics:

It has good impact resistance, the presence of chromium element makes its surface hardness high, can effectively resist wear and scratching. While ensuring hardness and strength, it has certain toughness and avoids excessive embrittlement. Often used in steel mills, coal preparation plants and other dry, high hardness block materials, such as: pellet materials, ore, gangue and so on.

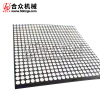

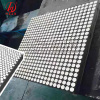

Composite ceramic liner:

Material characteristics:

In addition, the liner is suitable for wet and viscous materials with large water content. It is often used in coal preparation plants, ports and other massive materials with large water content, high viscosity or high hardness that are not subject to direct impact, such as coal slime with high water content and coke.

|

Types of Lining Board |

Specification |

Parameters |

|

Ceramic Lining Board |

20mm |

1. The alumina content of the lining board is ≥ 95% and the density is ≥ 3.6g/cm³. 2. Ceramic lining boards should be solid and able to withstand large material impacts for a long time. The service life shall not be less than 3 years. 3. Ceramic lining boards should be bonded with ceramic glue applied according to the standard process. The selected ceramic glue is BD1214KG, A and B slow - drying types, which has the advantages of fast bonding on - site, high bonding strength, acid resistance, alkali resistance, salt resistance, oil resistance, water resistance and aging resistance. 4. The hardness of wear - resistant ceramic chips (HRA) is ≥ 85, and the compressive strength is ≥ 850Mpa. Its wear resistance is more than 10 times that of high - chromium wear - resistant cast iron alloy pipe fittings. |

|

25mm |

||

|

30mm |

||

|

Overlay Welding Lining Board |

8mm + 8mm |

1. The base material is Q235. The overlay layer is welded with high - chromium wear - resistant wire. The chromium content of the wear layer is not less than 20%, the content of Cr7C3 eutectic carbide is not less than 50%, and the Rockwell hardness HRC is not less than 60. |

|

10mm + 10mm |

||

|

Wear - resistant Cast Steel |

20mm |

1. The chromium content of the high - chromium cast steel lining board is not less than 10%. 2. The hardness value of the high - chromium cast steel lining board is greater than HRC56. 3. The steel plate performance test shall comply with GB/T 709 - 2019. 4. The product surface should be flat without bending deformation and other defects affecting use. 5. The countersunk holes in the lining board should be free of burrs and rough edges, and be suitable for M16*60 socket head cap screws (GB/T 70.3 - 2008). |

|

Mirror Lining Board |

8mm + 8mm |

1. The lining board material is Q235 steel plate + mirror high - chromium material, using the alloy powder metallurgy process. |

|

10mm + 10mm |

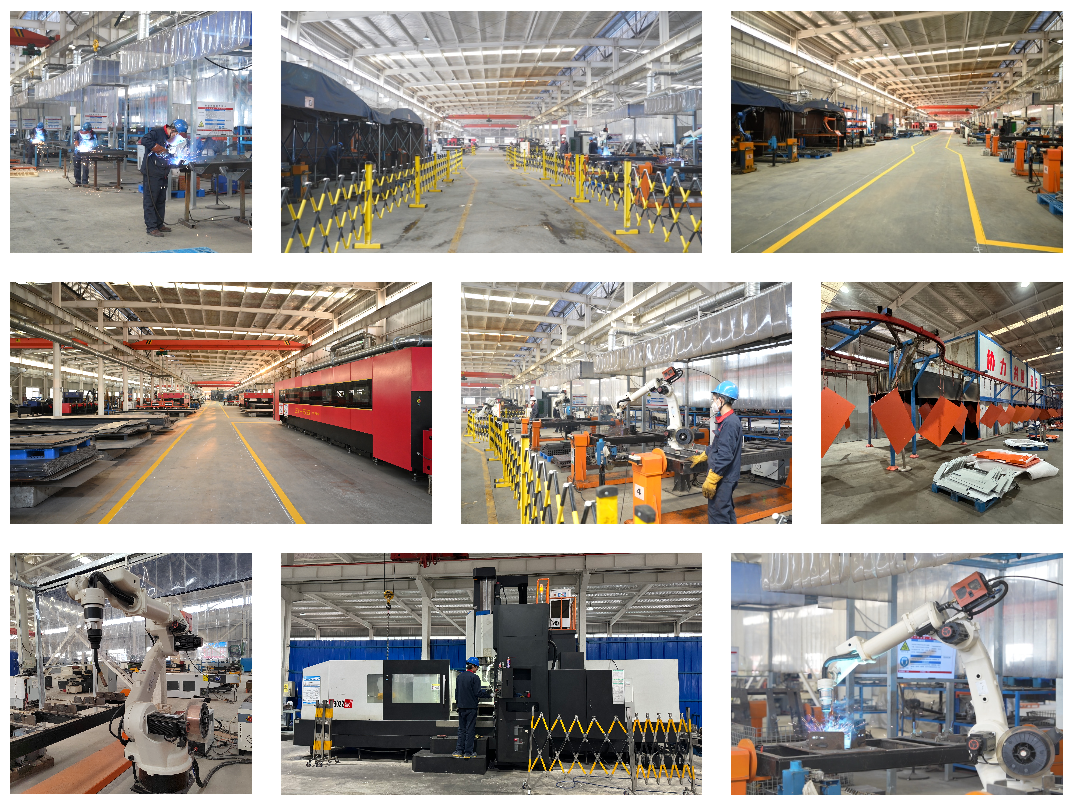

Workshop Real Shot Display

![loading... [318x238]](https://shopsource.singoo.cc/1987/general/ESdtSrSdX6PPt2xS/1725868784710777%E9%87%91%E9%92%B1%E5%85%9C-ECM-MD%E7%8E%AF%E4%BF%9D%E5%AF%BC%E6%96%99%E6%A7%BD_00.jpg?x-oss-process=image/resize)

![loading... [318x238]](https://shopsource.singoo.cc/1987/general/85h5T44fFsjAtx3Z/1725871670121122%E9%87%91%E9%92%B1%E5%85%9C-ECM-MD%E7%BC%93%E5%86%B2%E8%A3%85%E7%BD%AE_00.jpg?x-oss-process=image/resize)

![loading... [318x238]](https://shopsource.singoo.cc/1987/general/zmCcKftDXsJrWNTP/1725871731707170%E9%87%91%E9%92%B1%E5%85%9C-ECM-MD-%E7%BA%A0%E5%81%8F%E8%A3%85%E7%BD%AE_00.jpg?x-oss-process=image/resize)

![loading... [318x238]](https://shopsource.singoo.cc/1987/general/ryFdetymt2DfzKaJ/1725871779547696%E9%87%91%E9%92%B1%E5%85%9C-ECM-MD-%E6%B8%85%E6%89%AB%E8%A3%85%E7%BD%AE_00.jpg?x-oss-process=image/resize)

![loading... [318x238]](https://shopsource.singoo.cc/1987/general/fDx5KewBirMTckBw/1725871837638704%E9%87%91%E9%92%B1%E5%85%9C-ECM-MD%E6%9B%B2%E7%BA%BF%E8%90%BD%E6%96%99%E7%AE%A1_00(1).jpg?x-oss-process=image/resize)

![loading... [318x238]](https://shopsource.singoo.cc/1987/general/5PrxGYzndAS7hemr/1725871837638704%E9%87%91%E9%92%B1%E5%85%9C-ECM-MD%E6%9B%B2%E7%BA%BF%E8%90%BD%E6%96%99%E7%AE%A1_00.jpg?x-oss-process=image/resize)

![loading... [318x238]](https://shopsource.singoo.cc/1987/general/4fmC8rPYftrZtxED/1726018676687807%E9%87%91%E9%92%B1%E5%85%9C-ECM-ATEX_00.jpg?x-oss-process=image/resize)

![loading... [318x238]](https://shopsource.singoo.cc/1987/general/CzS52zWnAthpGx8R/1726018719188041%E9%87%91%E9%92%B1%E5%85%9C-ECM-MD-%E6%89%98%E8%BE%8A_00.jpg?x-oss-process=image/resize)